Innovation From Design To Production

Advanced Engineering / New Product Development

Zoongan is a dedicated partner in new product development. Our team of engineers, program managers, and project managers is committed to collaborating closely, starting from the initial part and process designs. We begin by comprehensively understanding the product’s essential features and applications, as well as identifying any associated risks that might influence the tooling concept.

Utilizing 3-D design tools, we’ll craft tailored solutions with an emphasis on cost efficiency, manufacturability, and consistent processes. Our team will leverage its engineering expertise and extensive experience in metal forming to craft a top-tier tool or process while minimizing expenses.

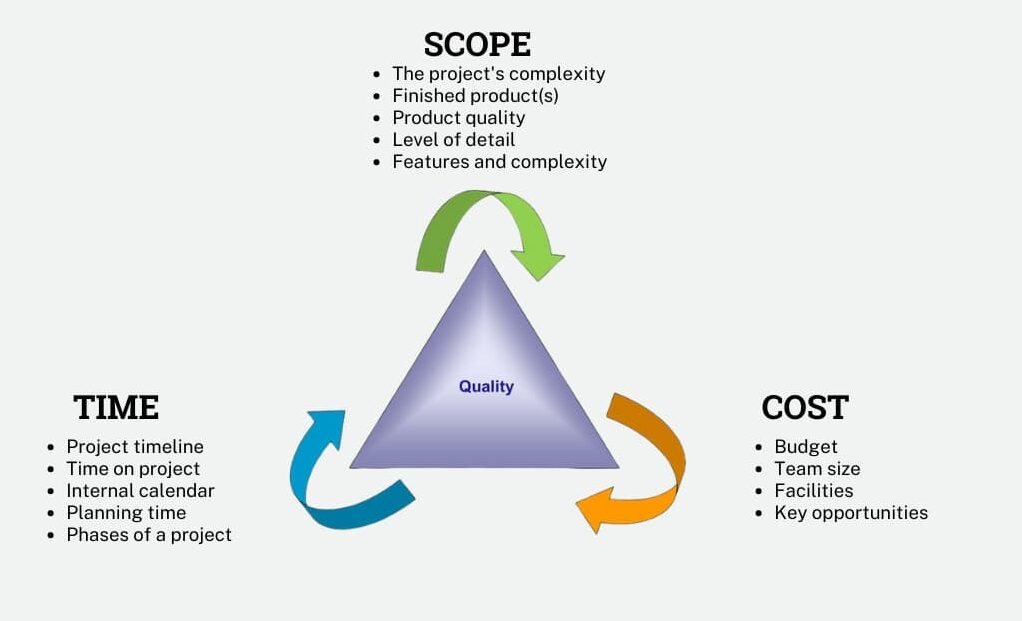

Project Management

When engaging with Zoongan, a Program Manager will be assigned, dedicated to the project’s success and best tooling interests in mind. The Program Manager will take charge of the project’s schedule. At the project’s outset, they will layout a detailed timeline, serving as the foundation for tracking the project’s progress from start to finish. This includes monitoring milestones such as PPAP & SOP approvals, where applicable.

The assigned Program Manager will also oversee any subcontractors or suppliers involved in the project’s supply chain, should we decide to award subcontracts for additional machinery or processes. They will provide regular updates on the project’s status, whether it pertains to prototypes, tool and gauge build, or advancements in automated welding, staking machines, or robotic carrying tools.

Our management team will conduct on-site visits to the facility, aiming to gain a comprehensive understanding of the assembly process while gathering essential information regarding the product’s fit and functionality and return this info to the team working on the project.

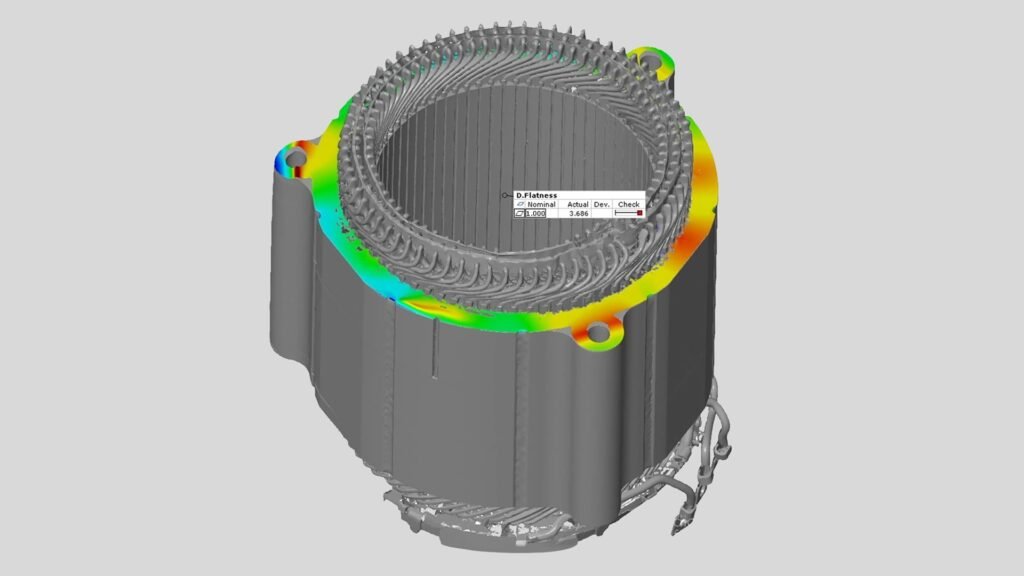

Following the launch of the product, our Quality Assurance (QA) department will uphold the highest quality standards during the manufacturing process. This is accomplished through the utilization of Faro Arm Laser Scanning and probing and other precise instruments.

We maintain consistent communication to facilitate an ongoing process of continuous improvement. If deemed necessary, we will work collaboratively to fine-tune aspects of the product’s design or build to ensure optimal performance and satisfaction.

Simulation & Design Services

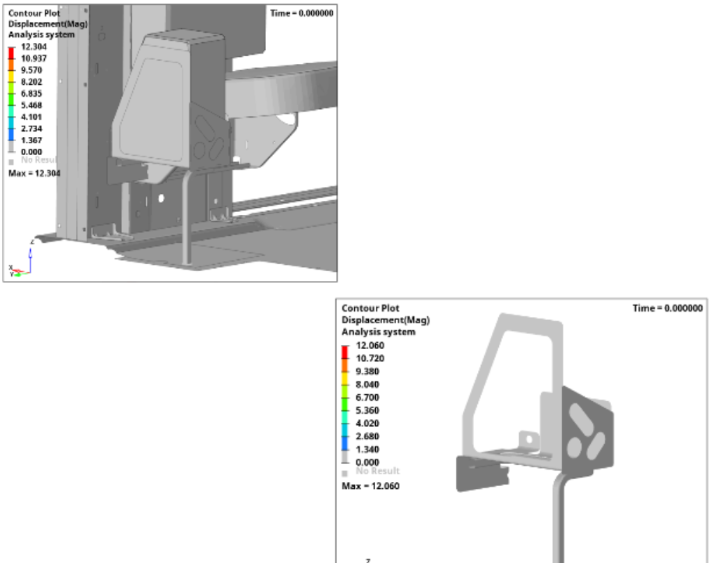

Our Simulation and Design services are underpinned by the use of advanced 3-D design tools. These tools allow our adept engineers to create highly detailed and precise design plans. These plans serve as the foundation for product development, ensuring that every component and process is meticulously planned.

We understand that every project is unique, and our approach involves customizing solutions to meet specific needs. This level of customization allows us to address particular challenges and goals, whether developing a new product or enhancing an existing one.

The 3-D design tools we employ enable us to create designs that simplify the manufacturing process. This simplicity is valuable in the production phase, reducing the likelihood of errors, speeding up production, and ensuring that the final product aligns with expectations.

Our approach is dedicated to fostering innovation. Through the provision of tailored design solutions, we enable the transformation of creative ideas into tangible products, whether it involves the creation of new products or the enhancement of existing ones. Our Simulation and Design services play a pivotal role in this process.